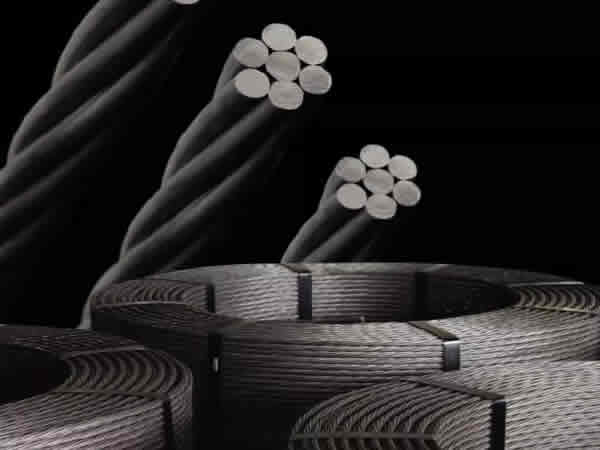

PC Steel Strand

Low Relaxation Prestressed Concrete Steel Wire Strand, normally we call it PC STRAND production process has strict quality. PC Strand (Bonded Prestressed Concrete Wire Strand) are made of high carbon steel wire rods, which are cold-drawn into steel wires after surface treatment, and then a certain amount of steel wires are synthesized into strands, and then subjected to a stress-relieving stabilization process. To extend durability, the wire can be coated with a metal or non-metal coating or coating such as galvanized or epoxy. To increase the grip strength of the concrete, the surface can be scored. Unbonded prestressed steel strands are made of ordinary prestressed steel strands, coated with antiseptic grease or paraffin and coated with high density polyethylene(HDPE).

Common sizes: 9.3mm,9.53mm,11.11mm,11.3mm,12.5mm,12.7mm,15.24mm,15.7mm.

Raw Materials: High-carbon steel wire rods, SWRH 82B,SWRH77B

Features:

1)High tensile strength, low relaxation, stable modulus of elasticity, stress-relieved, firm connection with concrete, low stress, stable construction, good combination with steel reinforced concrete; saving material, reducing distortion and construction weight, increasing the abrasion resistance, water resistance, stiffness.

2)We offer PC Strand which confirm to the technical standards such as GB/T 5223, GB/T 5224, ASTM A-416, BS 5896, JIS G3536 or the standards agreed by both of the customers and us.

3)PC strand can also be supplied in various forms for pre- or post-tensioning applications, with plain or galvanized material ranging from 3 wires, 7 wires, 19 wire and compacted construction.

Application

1)Our PC strand is mainly used for the reinforcement of prestressed concrete structures, such as large-span railway and road bridges, major bridges, silos, buildings, dams, floor slabs, foundations, large concrete vessels, atomic reactor buildings, stadiums, airport hangers, pre-cast segments, crane beams, anchorages and multi-storey industrial buildings etc.

2)Our PC strand is also used for the construction of highways, poles and water towers in civil construction, and energy source sea transportation, house buildings, water control projects, and rock and earth anchoring components to increase the tensile force.

| Strand Structure | Nominal Diameter | Strand Diameter Tolerance /mm | Strand reference sectional area Sn/mm2 | Strand reference quality per meter/(g/m) | |

| Strand Diameter Dn/mm | Wire Diameter d/mm | ||||

| 1×2 | 5.00 | 2.50 | +0.15 -0.05 | 9.82 | 77.1 |

| 5.80 | 2.90 | 13.2 | 104 | ||

| 8.00 | 4.00 | +0.25 -0.10 | 25.1 | 197 | |

| 10.00 | 5.00 | 39.3 | 309 | ||

| 12.00 | 6.00 | 56.5 | 444 | ||

| Strand Structure | Nominal Diameter | Strand Measurement A/mm | Measurement A Tolerance /mm | Strand reference sectional area Sn/mm2 | Strand reference quality per meter/(g/m) | |

|---|---|---|---|---|---|---|

| Strand Diameter Dn/mm | Wire Diameter d/mm | |||||

| 1×3 | 6.20 | 2.90 | 5.41 | +0.15 -0.05 | 19.8 | 155 |

| 6.50 | 3.00 | 5.60 | 21.2 | 166 | ||

| 8.60 | 4.00 | 7.46 | +0.20 -0.10 | 37.7 | 296 | |

| 8.74 | 4.05 | 7.56 | 38.6 | 303 | ||

| 10.80 | 5.00 | 9.33 | 58.9 | 462 | ||

| 1×3 I | 12.90 | 6.00 | 11.20 | 84.8 | 666 | |

| 8.74 | 4.05 | 7.56 | 38.6 | 303 | ||

| Strand Structure | Nominal Diameter Dn/mm | Diameter Tolerance /mm | Strand reference sectional area Sn/mm2 | Strand reference quality per meter/(g/m) | Center wire diameter (do) enlarged range/% not less than |

|---|---|---|---|---|---|

| 1×7 | 9.50 | +0.30 -0.15 | 54.8 | 430 | 2.5 |

| 11.10 | 74.2 | 582 | |||

| 12.70 | +0.40 -0.20 | 98.7 | 775 | ||

| 15.20 | 140 | 1101 | |||

| 15.70 | 150 | 1178 | |||

| 17.80 | 191 | 1500 | |||

| (1×7)C | 12.70 | +0.4 -0.20 | 112 | 890 | |

| 15.20 | 165 | 1295 | |||

| 18.00 | 223 | 1750 |

| trand Structure | Strand nominal diameter Dn/mm | Abstract tensile strength Rm/Mpa not less than | The largest force of the whole strand Fm/kN not less than | Rated non-proportional extension force | Total extension ratio at the largest force (Lo≥400)Agt/% not less than | Stress Relaxation | |

|---|---|---|---|---|---|---|---|

| Initial load equivalent to the percentage of the nominal largest force/% | After 1000h stress relaxation rate r/% not less than | ||||||

| 1×2 | 5.00 | 1570 | 15.4 | 13.9 | 3.5 | 60 70 80 | 1.0 2.5 4.5 |

| 1720 | 16.9 | 15.2 | |||||

| 1860 | 18.3 | 16.5 | |||||

| 1960 | 19.2 | 17.3 | |||||

| 5.80 | 1570 | 20.7 | 18.6 | ||||

| 1720 | 22.7 | 20.4 | |||||

| 1860 | 24.6 | 22.1 | |||||

| 1960 | 25.9 | 23.3 | |||||

| 8.00 | 1470 | 36.9 | 33.2 | ||||

| 1570 | 39.4 | 35.5 | |||||

| 1720 | 43.2 | 38.9 | |||||

| 1860 | 46.7 | 42.0 | |||||

| 1960 | 49.2 | 44.3 | |||||

| 10.0 | 1470 | 57.8 | 52.0 | ||||

| 1570 | 61.7 | 55.5 | |||||

| 1720 | 67.6 | 60.8 | |||||

| 1860 | 73.1 | 65.8 | |||||

| 1960 | 77.0 | 69.3 | |||||

| 12.00 | 1470 | 83.1 | 74.8 | ||||

| 1570 | 88.7 | 79.8 | |||||

| 1720 | 97.2 | 87.5 | |||||

| 1860 | 105 | 94.5 | |||||

| Note: Rated non-proportional extension force Fp0.2 is not less than 90% of the largest force of the whole strand | |||||||

| Strand Structure | Strand nominal diameter Dn/mm | Abstract tensile strength Rm/Mpa not less than | The largest force of the whole strand Fm/kN not less than | Rated non-proportional extension force | Total extension ratio at the largest force (Lo≥400)Agt/% not less than | Stress Relaxation | |

|---|---|---|---|---|---|---|---|

| Initial load equivalent to the percentage of the nominal largest force/% | After 1000h stress relaxation rate r/% not less than | ||||||

| 1×3 | 6.20 | 1570 | 31.1 | 28.0 | 3.5 | 60 70 80 | 1.0 2.5 4.5 |

| 1720 | 34.1 | 30.7 | |||||

| 1860 | 36.8 | 33.1 | |||||

| 1960 | 38.8 | 34.9 | |||||

| 6.50 | 1570 | 33.3 | 30.0 | ||||

| 1720 | 36.5 | 32.9 | |||||

| 1860 | 39.4 | 35.5 | |||||

| 1960 | 41.6 | 37.4 | |||||

| 8.60 | 1470 | 55.4 | 49.9 | ||||

| 1570 | 59.2 | 53.3 | |||||

| 1720 | 64.8 | 58.3 | |||||

| 1860 | 70.1 | 63.1 | |||||

| 1960 | 73.9 | 66.5 | |||||

| 8.74 | 1570 | 60.6 | 54.5 | ||||

| 1670 | 64.5 | 58.1 | |||||

| 1860 | 71.8 | 64.6 | |||||

| 10.80 | 1470 | 86.6 | 77.9 | ||||

| 1570 | 92.5 | 83.3 | |||||

| 1720 | 101 | 90.9 | |||||

| 1860 | 110 | 99.0 | |||||

| 1960 | 115 | 104 | |||||

| 12.90 | 1470 | 125 | 113 | ||||

| 1570 | 133 | 120 | |||||

| 1720 | 146 | 131 | |||||

| 1860 | 158 | 142 | |||||

| 1960 | 166 | 149 | |||||

| 8.74 | 1570 | 60.6 | 54.5 | ||||

| 1670 | 64.5 | 58.1 | |||||

| 1860 | 71.8 | 64.6 | |||||

| Note: Rated non-proportional extension force Fp0.2 is not less than 90% of the largest force of the whole strand | |||||||

| Strand Structure | Strand nominal diameter Dn/mm | Abstract tensile strength Rm/Mpa not less than | The largest force of the whole strand Fm/KN not less than | Rated non-proportional extension force | Total extension ratio at the largest force (Lo≥400)Agt/% not less than | Stress Relaxation | |

|---|---|---|---|---|---|---|---|

| Initial load equivalent to the percentage of the nominal largest force/% | After 1000h stress relaxation rate r/% not less than | ||||||

| 1×7 | 9.50 | 1720 | 94.3 | 84.9 | 3.5 | 60 70 80 | 1.0 2.5 4.5 |

| 1860 | 102 | 91.8 | |||||

| 1960 | 107 | 96.3 | |||||

| 11.10 | 1720 | 128 | 115 | ||||

| 1860 | 138 | 124 | |||||

| 1960 | 145 | 131 | |||||

| 12.70 | 1720 | 170 | 153 | ||||

| 1860 | 184 | 166 | |||||

| 1960 | 193 | 174 | |||||

| 15.20 | 1470 | 206 | 185 | ||||

| 1570 | 220 | 198 | |||||

| 1670 | 234 | 211 | |||||

| 1720 | 241 | 217 | |||||

| 1860 | 260 | 234 | |||||

| 1960 | 274 | 247 | |||||

| 15.70 | 1770 | 266 | 239 | ||||

| 1860 | 279 | 251 | |||||

| 17.80 | 1720 | 327 | 294 | ||||

| 1860 | 353 | 318 | |||||

| (1×7)C | 12.70 | 1860 | 208 | 187 | |||

| 15.20 | 1820 | 300 | 270 | ||||

| 18.00 | 1720 | 384 | 346 | ||||

| Note: Rated non-proportional extension force Fp0.2 is not less than 90% of the largest force of the whole strand | |||||||